In today's frontline workplaces, flexibility isn't optional. It's the key to reducing absenteeism, retaining top talent, improving morale, and saving costs.

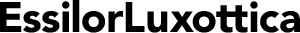

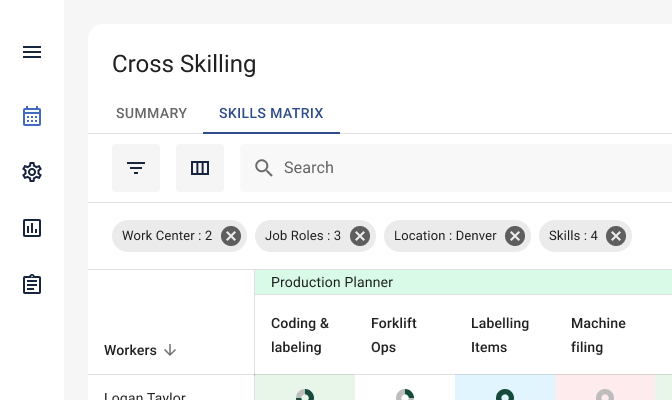

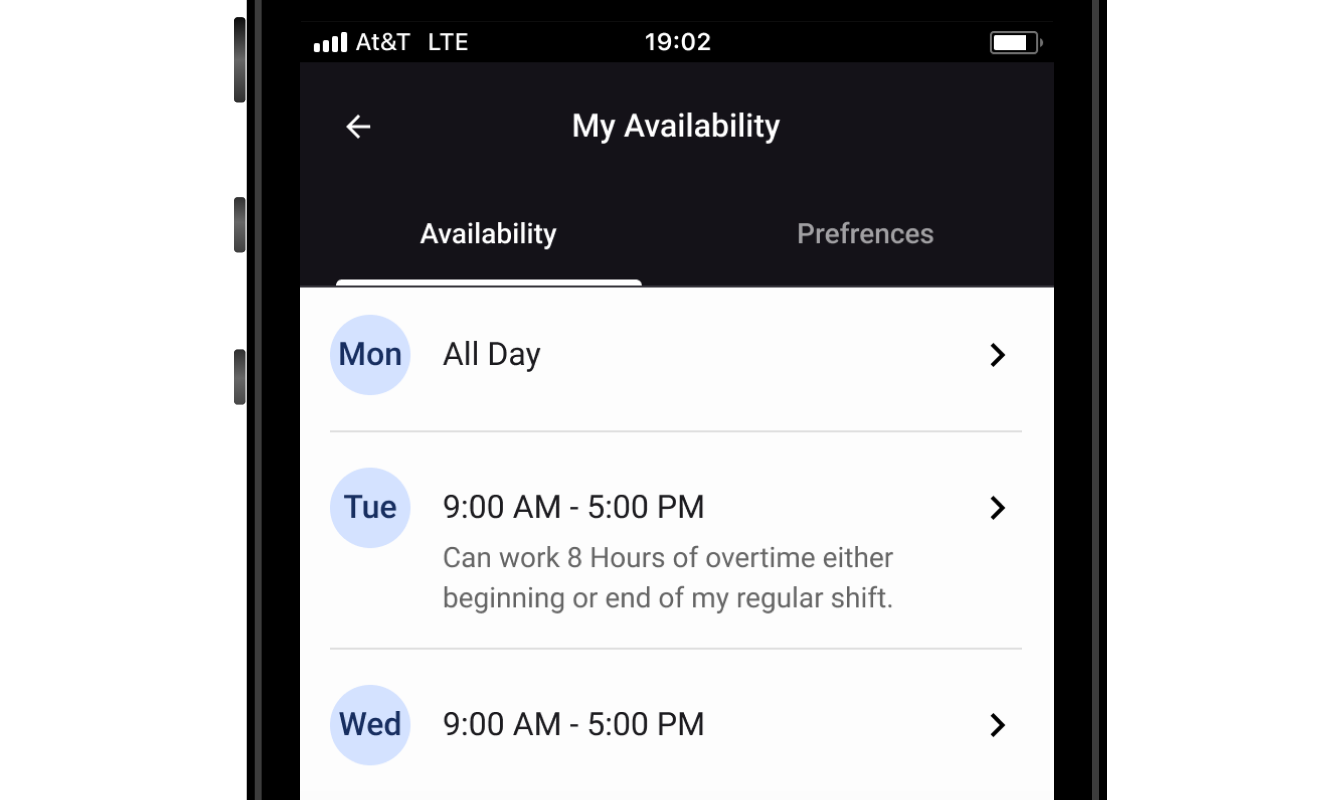

But real flexibility requires more than shift swaps and spreadsheets. It needs structure, visibility, skill-based intelligence.

That's where Wilya comes in.